7/8" Corrugated Panel System

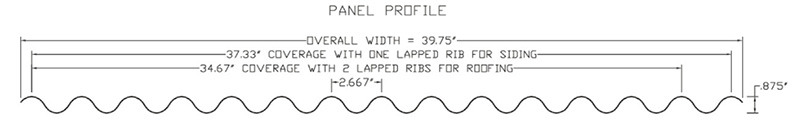

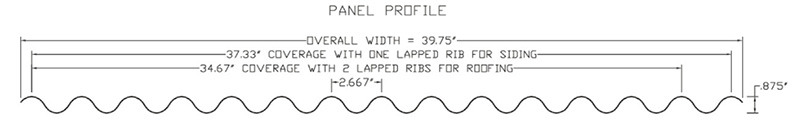

Panel Dimensions

- Coverage Width Siding: 37.33” Roofing: 34.67”

- Rib Pitch 2.67”

- Profile Depth 0.875”

- Thickness .032 Aluminum, .040 Aluminum, 22 ga. Steel, 24 ga. Steel

- Weight 0.471 lb/ft2, 0.585 lb/ft2, 0.1.25 lb/ft2, 1.00 lb/ft2

Material Specifications

3000 Series Alloy in compliance with the Aluminum Association Composition Specifications and

conforming to ASTM B209 is standard.

Product Notes

- Remove the protective film quickly after installation.

- Panels should be laid flat in a dry, indoor environment during storage.

- Panels should always be lapped against prevailing winds

- Typical side lap spacing is 18”. Consult a Professional Engineer for specific requirements, as this

may not be appropriate for all applications.

- ⅛”x½” tape sealant shall be used at all side laps when used as a roof panel.

- When using this panel in a roofing application, it should be lapped two corrugations. Panels may

be lapped one corrugation when used in a siding application.

- Minimum recommended roof slope: 2:12

- Available through various manufacturers

General Information

Corrugated panels provided superior flexibility for use as a wall or roofing panel. The 7/8″ panel has

excellent negative load capability even for high-wind pressures. The Corrugated panels can be produced

perforated for a variety of exterior projects, such as equipment screens. Perforated corrugated panels

are also highly suitable for interior acoustical applications as well.

Testing

- ASTM E283

- ASTM E1592

- ASTM E1646